In the material transportation systems of mining, logistics, and manufacturing industries, conveyors are like the "arteries", while idlers, as core components that support the conveyor belt and reduce friction, their installation quality directly determines the operational efficiency and service life of the conveyor. Although Conveyor Idler installation seems simple, it actually involves many key details. Improper operation will not only increase the risk of equipment failure but also may affect the stable operation of the entire production line.

The traditional idler installation often has the problem of "prioritizing speed over precision". Some construction workers rely on experience for judgment and do not conduct accurate benchmark positioning, resulting in the coaxiality deviation of idlers exceeding 1.5mm. This makes the conveyor belt prone to deviation during operation, and the monthly material loss caused by deviation can reach the ton level. At the same time, the improper control of bolt tightening torque—too loose will lead to loose idlers and abnormal noise, while too tight will easily cause bearing damage. The average quarterly maintenance cost caused by installation problems exceeds 10,000 yuan, which seriously slows down the production progress.

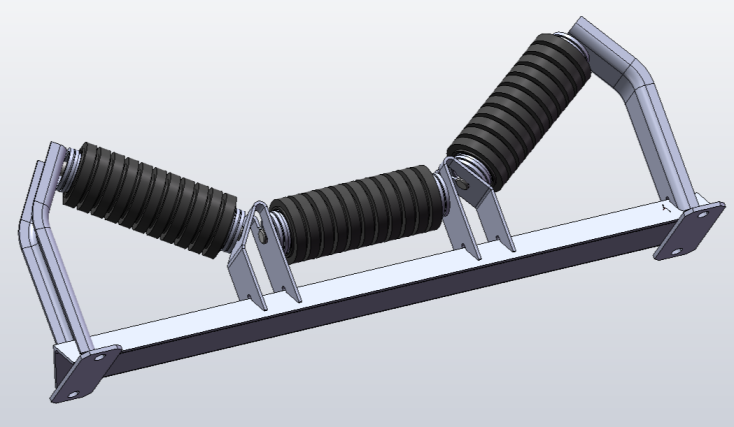

Scientific idler installation must follow the three principles of "accurate positioning, standardized operation, and adapting to working conditions". Firstly, use a laser locator to determine the reference line of the idler bracket, ensuring that the coaxiality error of each group of idlers is controlled within 0.8mm, so as to avoid conveyor belt deviation from the source. Secondly, use a torque wrench to tighten the bolts according to the standard torque. The torque is set between 25-40N・m depending on the idler model, balancing the fastening stability and component protection. Finally, optimize the installation plan according to different working conditions: install a sealing rubber ring in a high-dust environment to prevent impurities from entering the bearing; select low-temperature resistant grease in a low-temperature environment to ensure the flexible rotation of the idler.

Tests have proved that if the idler is installed irregularly, the conveyor will shut down an average of 2-3 times per month, with each maintenance taking more than 4 hours. After adopting the standardized installation process, the idler coaxiality error is reduced to below 0.5mm, the bolt tightening qualification rate reaches 100%, the equipment shutdown frequency is reduced to less than 0.5 times per month, the annual maintenance cost is saved by more than 120,000 yuan, the service life of the conveyor belt is extended by 30%, and the logistics sorting efficiency is increased by 15%.

Currently, the industrial production has increasingly high requirements for the continuous operation of equipment. The conveyor idler installation has been upgraded from a "basic operation" to a "refined project". Enterprises need to attach importance to the professional training of installation personnel, establish installation quality acceptance standards, and incorporate the idler installation accuracy into the equipment operation and maintenance assessment system. In the future, with the integration of intelligent technology, the idler installation may combine digital twin technology to realize the visual monitoring and precise control of the installation process, further promoting the conveyor operation and maintenance towards a more efficient and intelligent direction, and laying a "stable transportation line of defense" for industrial production.