In heavy industrial fields such as mining, ports, and metallurgy, heavy-duty conveyors serve as the "main arteries" for material transportation, undertaking the task of conveying materials weighing hundreds or even thousands of tons. As the core load-bearing components of conveyors, idlers directly determine the stability, efficiency, and service life of the equipment. Like the "backbone" of the conveyor, they silently support the weight of the conveyor belt and materials, while significantly reducing operational resistance through rolling friction—making them a crucial link in ensuring the continuous operation of heavy-duty transportation systems.

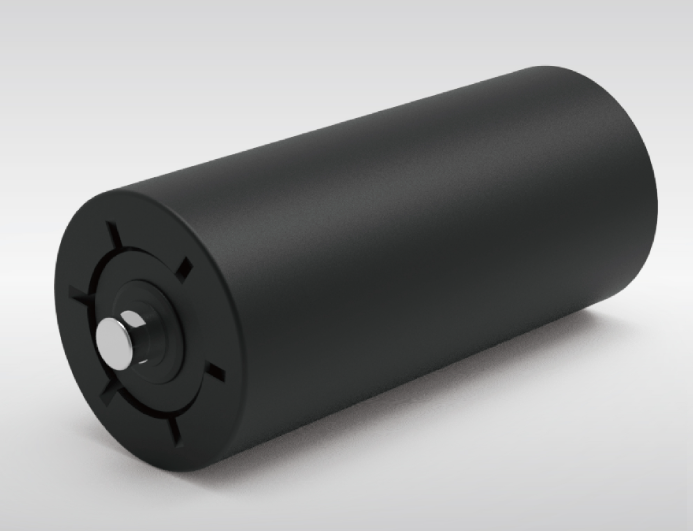

The structure of heavy conveyor idlers may seem simple, but it embodies strict requirements for strength and precision. They mainly consist of a roller body, bearing housings, bearings, a shaft, and a sealing device. As the component in direct contact with the conveyor belt, the roller body must possess high impact resistance and wear resistance. It is usually made of seamless steel pipes or high-strength cast iron; in some special working conditions, it is also treated with wear-resistant coatings to cope with long-term friction and impact from hard materials such as ore and coal. Bearing housings and shafts, on the other hand, need to be made of high-carbon steel and undergo quenching and tempering heat treatment to enhance toughness and strength, ensuring they do not easily deform or break under heavy loads. The sealing device is even more critical: adopting a multi-layer labyrinth or contact-type sealing structure, it can effectively block impurities such as dust and moisture from entering the interior of the bearings, preventing lubrication failure and significantly extending the service life of the idlers.

Compared with ordinary conveyor idlers, heavy-duty idlers differ vastly in performance parameters. Firstly, in terms of load-bearing capacity, a single set of ordinary idlers can usually bear several hundred kilograms, while heavy-duty idlers can easily handle several tons; some customized products can even withstand concentrated loads of more than ten tons. Secondly, in terms of speed adaptability, to match the high-efficiency transportation needs of heavy-duty conveyors, heavy-duty idlers must maintain stable operation under low-speed and heavy-load conditions, avoiding component damage caused by excessive centrifugal force. Additionally, temperature resistance and corrosion resistance are particularly important. In high-temperature environments in the metallurgical industry or humid, salt-laden environments in ports, idlers must have excellent environmental adaptability to ensure the year-round non-stop operation of the equipment.

With the development of industrial automation and intelligence, heavy conveyor idlers are also constantly upgrading and iterating. Today, some high-end idlers have been integrated with intelligent sensing modules, which can real-time monitor parameters such as operating temperature and vibration frequency. Through IoT (Internet of Things) technology, this data is transmitted to the central control system, enabling fault early warning and predictive maintenance, and significantly reducing downtime. At the same time, lightweight design has become a new trend. On the premise of ensuring strength, high-strength aluminum alloys or composite materials are used to make the roller body, which not only reduces the weight of the equipment itself but also lowers energy consumption—aligning with the development concept of green industry.

In practical applications, daily maintenance of idlers cannot be ignored either. Regularly checking the rotational flexibility, sealing status, and lubrication of idlers, and promptly replacing worn or seized idlers, can effectively prevent issues such as conveyor belt deviation and accelerated wear, and extend the overall service life of the conveyor. It can be said that although heavy conveyor idlers are "small components," they bear "great responsibilities." Their performance and quality are directly related to the efficiency and safety of heavy industrial production, making them an indispensable core part of modern heavy-duty transportation systems.