First, the working principle of the belt conveyor

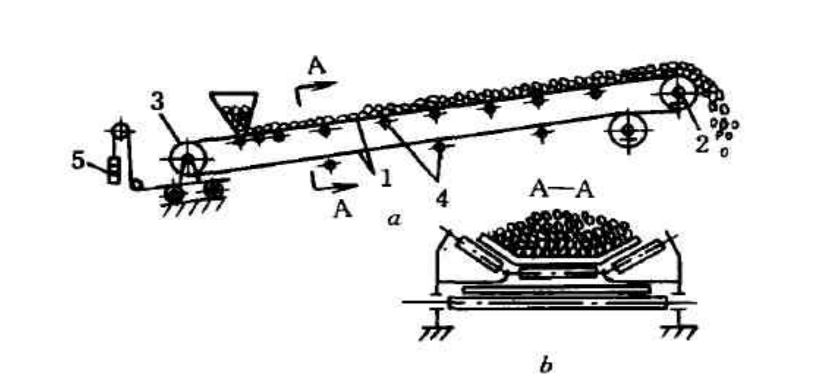

As shown in the figure below, the belt conveyor is mainly composed of several parts, such as the belt, the transmission roller, the tensioning device, the roller frame and the transmission device

After the tape is wound through the rollers at both ends, the two ends are connected together with the tape clip or vulcanization method to make it a closed-loop structure. The tape is carried by the upper and lower rollers, and the tape is tightened by a tensioning device, which has a certain tension. When the driving drum is driven by a motor and rotates, with the help of the friction between the driving drum and the tape, the belt runs continuously, so that the load loaded on the tape is unloaded from the unloading drum 2.

Second, the transmission principle and characteristics of the belt conveyor

(1) The traction force of the belt conveyor is transmitted by the friction between the transmission drum and the belt, so the belt must be tightened with a tensioning device, so that the belt has a certain initial tension at the separation of the drum conveyor.

(2) The tape runs on the roller together with the cargo load. The tape is both a traction mechanism and a carrying machine

There is no relative movement between the load and the belt, which eliminates the friction resistance between the belt and the load during operation. Because the roller is equipped with a rolling bearing, there is rolling friction between the belt and the roller, so the running resistance is greatly reduced, thereby reducing the power consumption and increasing the transportation distance. For a belt conveyor, its traction transmission capacity is determined by the tension of the belt, the wrapping angle of the belt on the transmission pulley, and the friction coefficient between the belt and the transmission pulley. In order to ensure that the belt of the belt conveyor does not slip on the transmission drum and operates normally, corresponding measures should be taken according to different situations in production practice. Improving traction delivery can be done in the following ways:

(1) Increase the tension force (initial tension). In the operation of the belt conveyor, the belt should be elongated, resulting in a decrease in traction, so according to the situation, the belt should be properly tightened by using a tensioning device to increase the belt

tension to improve traction. (2) Increase the coefficient of friction. The specific measures are: protect the wooden lining or rubber and other liners covered on the transmission drum to increase the friction coefficient, and the other side should produce less water and coal to prevent the friction coefficient from decreasing. (3) Increase the wrapping angle. Due to the poor working conditions and large traction required by the belt conveyor, double roller transmission is mostly used to increase the encirclement angle.