In the complex network of material handling systems, conveyor rollers stand as the unsung heroes, facilitating the smooth transport of goods across industries ranging from manufacturing to logistics. However, even the most durable rollers face wear and tear over time, making conveyor roller replacement parts indispensable for maintaining operational efficiency. These components not only extend the lifespan of conveyor systems but also prevent costly downtime, which can disrupt production schedules and erode profitability.

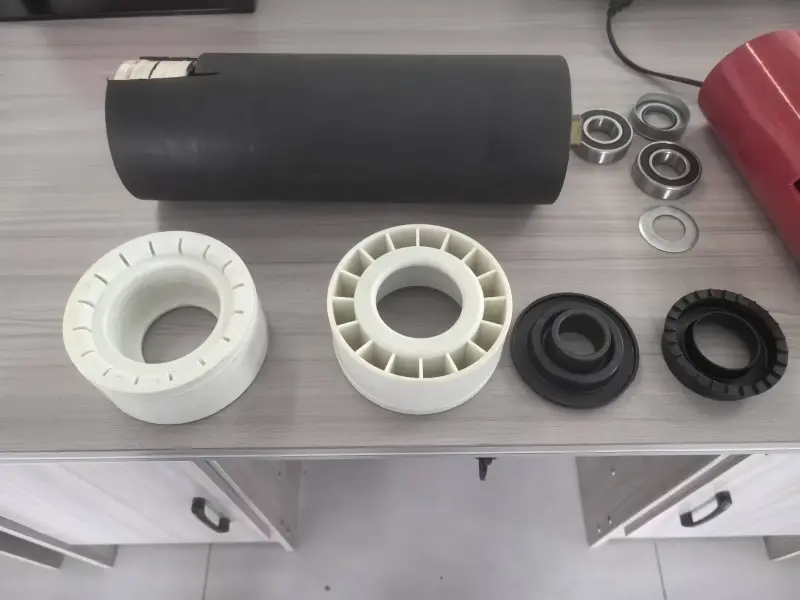

Conveyor roller replacement parts encompass a wide range of components, each playing a critical role in the roller’s functionality. The roller bearings are among the most vital, reducing friction between the rotating roller and its fixed axle. High-quality bearings, typically made from stainless steel or ceramic, ensure quiet operation and resistance to corrosion—essential for environments like food processing or pharmaceuticals where hygiene and durability are paramount. Another key part is the roller shell, which comes in materials such as galvanized steel, plastic, or rubber. Steel shells excel in heavy-duty applications, while rubber or plastic variants are ideal for delicate goods that require gentle handling, such as electronics or packaged foods. Additionally, shafts and end caps provide structural support, ensuring the roller remains aligned and stable during operation.

Selecting the right replacement parts is a decision that directly impacts the performance of the conveyor system. Compatibility is the first priority: parts must match the roller’s size, load capacity, and design specifications. For instance, a roller designed for a 500kg load cannot accommodate a bearing rated for 300kg, as this would lead to premature failure. Material selection is equally crucial, as it must align with the operating environment. In wet or dusty settings, corrosion-resistant parts like zinc-plated shafts or sealed bearings prevent rust and debris buildup, which can jam the roller. Moreover, opting for parts from reputable manufacturers ensures compliance with industry standards, guaranteeing reliability and safety.

Proactive maintenance and timely replacement of parts are key to minimizing operational risks. Regular inspections, such as checking for bearing noise, roller misalignment, or shell damage, can identify potential issues before they escalate. When replacement is necessary, following proper installation procedures is critical. For example, over-tightening bearings can cause excessive friction, while loose end caps can lead to roller instability. Many businesses also invest in spare parts inventory, ensuring that critical components like bearings or shafts are readily available to reduce downtime.

In conclusion, conveyor roller replacement parts are the backbone of efficient material handling systems. From ensuring smooth operation with high-quality bearings to adapting to diverse environments with durable shells, these components play a pivotal role in maintaining productivity. By prioritizing compatibility, material selection, and proactive maintenance, businesses can extend the lifespan of their conveyor systems, reduce costs, and ensure uninterrupted operations in an increasingly competitive landscape.