The analysis and design of the roller production line should be considered from the two aspects of processing technology and main line logistics, and the logistics design of the production line serves the production task and must meet the overall requirements of the production operation for the main line logistics system. Its main purpose is to improve the efficiency of the entire production line, reduce the labor intensity of workers, and reduce logistics costs. The production logistics system of the carrier is closely linked with its entire production process, the material is accompanied by the process of roller processing from the previous process into the next process, in fact, the production logistics has become an important part of the process, the process is: raw materials and other materials start from the warehouse, enter the beginning of the roller production line, and then flow between the various stations according to the process route of the roller processing, in the process of flowing, the roller processing, and finally enter the finished product warehouse.

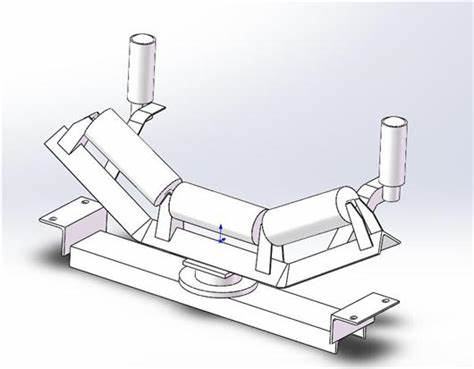

The processing and manufacturing of idlers is a typical discrete intermittent flow production mode. The whole production line should be reasonably laid out in accordance with the process flow of roller production. Although the number of roller production and processing equipment is small, there is a large difference in the production rate of different equipment. The raw materials of the roller production line arrive in batches periodically, and the rollers to be processed between each station are transported through the roller table frame, and the conveying distance between each station is determined according to the actual situation, and a buffer area is set between the workstations. The main line logistics of the production line adopts non-dynamic type, and the circulation of the pipe body in each station adopts a mechanical method, that is, the automatic loading and unloading system of the pipe body is adopted. Bearings, seals and retaining rings can be installed manually or by a special loader. The main line logistics of the pallet production line mainly includes the design of the main line roller table frame, the design of the automatic loading and unloading system of the pipe body, etc.