Design and Function

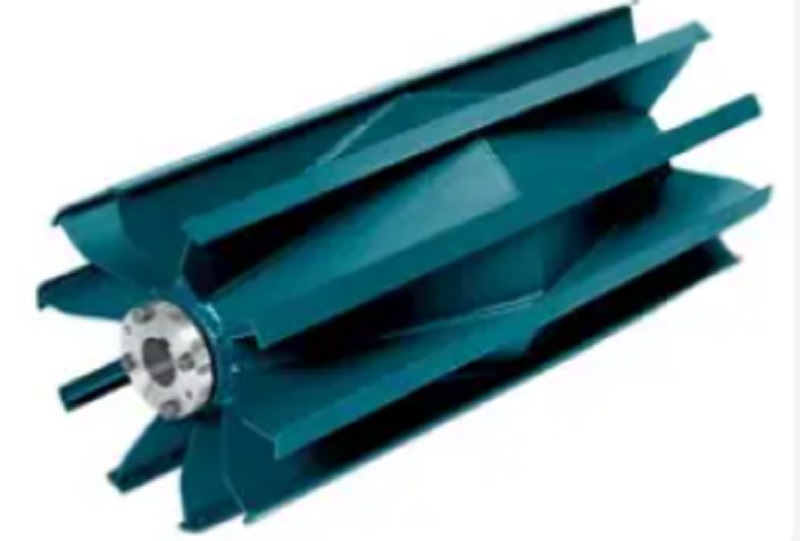

The core design feature of a wing pulley is radial "wings" (usually steel bars or plates) extending outward from the circumference of the pulley. These wings primarily serve two main functions:

●Material shedding: V-shaped or herringbone patterns (herringbone wing pulleys) can actively push scattered materials (such as stones, debris) away from the contact interface between the pulley and the conveyor belt, preventing material retention from causing conveyor belt punctures, mistracking, or wing deformation.

●Conveyor belt cleaning: The intermittent contact between the wings and the conveyor belt generates a slapping action, which can remove materials adhering to the conveyor belt, reduce "carryback", and extend the service life of the conveyor belt by up to 30% compared to traditional pulleys.

Key Advantages

●Extending conveyor belt lifespan: By reducing material jamming and wing bending, it minimizes wear and structural damage to the conveyor belt. For example, the capless design of herringbone pulleys allows the use of thicker wings, further enhancing durability.

●Reducing noise and vibration: Continuous contact designs (such as spiral wing pulleys) can reduce noise by up to 50 decibels compared to traditional wing pulleys, improving workplace safety and operational efficiency.

●Customized solutions: Manufacturers offer a variety of variants, including heavy-duty mining models (with additional reinforcing ribs) and noise-optimized designs for grain conveying, among others.

Industrial Applications

●Conveyor systems: Commonly used in positions prone to material accumulation, such as tail pulleys, snub pulleys, and bend pulleys. For instance, in coal mines, herringbone wing pulleys (a hybrid of spiral and wing designs) can more effectively address dust and clogging issues compared to traditional spiral pulleys.

●Harsh environments: For high-wear scenarios, relevant technologies can be utilized, with their specialized coatings significantly enhancing wear resistance.

Technical Considerations

●Conveyor belt speed and pulley size: It is necessary to balance the centrifugal force generated by the rotating pulley to prevent materials from being thrown back onto the conveyor belt. For example, a pulley with a diameter of 20 inches operating at 310 feet per minute (FPM) may require design adjustments to prevent material recontamination.

●Maintenance points: Regular inspection of wing integrity and bearing lubrication (e.g., pulleys designed for easy shaft replacement) is crucial for preventing failures.

In summary, wing pulleys are crucial for optimizing conveyor performance in harsh environments. Their design achieves a balance between durability, efficiency, and cost-effectiveness, and continues to evolve to meet the challenges of modern bulk material conveying.