In view of the above problems in the previous news, there are two solutions: one is to move the coal cleaner forward, so that the cleared coal is directly pulled away on the previous belt; The second is to increase the height of the roadway, so that the transfer point of the front and rear two belts has sufficient height within a certain range. Then process a coal dustpan to let the cleared coal slip through the dustpan into the previous belt. However, sometimes due to the limitation of underground space and construction technology, it is very difficult to increase the height of the roadway.

Analyze the several scenarios discussed:

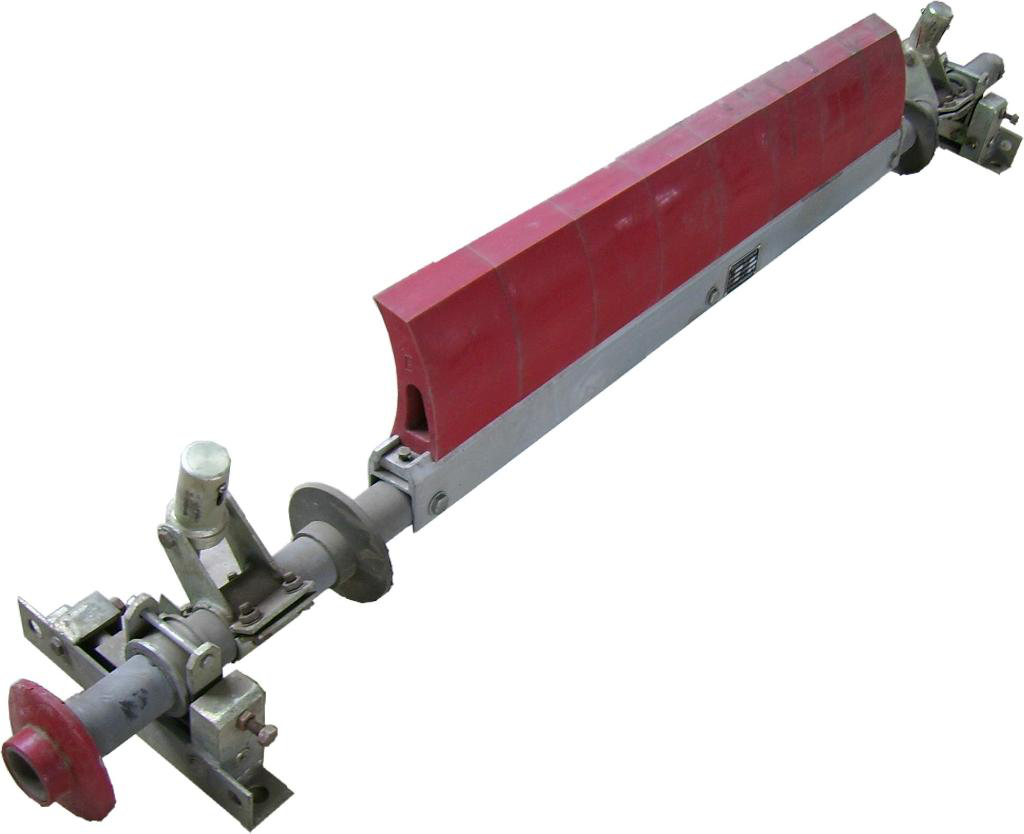

Scheme 1: Adopt a fully mechanical cleaning device, and the specific structure is composed of a guide rod, a beam, a cleaning and a bomb. The design concept is to tighten the beam and the rod through the spring, and ensure that the position of point A does not move under the joint action of the spring and the guide rod. With the wear of the cleaning block, the position of point A gradually deviates from the installation position, and the position of point A is kept in the optimal position by manually adjusting the position of the guide rod.

The advantages of this scheme are:

1. Simple structure, low cost and easy to manufacture.

2. The mechanism adopts secondary cleaning to make the cleaning effect more thorough.

Disadvantages and problems:

1. The mechanism has fewer constraints, resulting in the uncertainty of the position of the mechanism, especially in the design, it is not easy to determine its specific position, and the cleaning process cannot be realized, and even accidents may occur in the process of use.

2. The spring adopts a stretch spring, which increases the difficulty of installation and is not easy to achieve the requirements of convenient installation

Scheme 2: Adopt a mechanical sliding guide rod mechanism

The advantages of this scheme are:

1. It is easy to install and easy to realize the cleaning function.

2. Due to the addition of the pendulum, the operation is simpler and the workload of workers is greatly reduced.

Disadvantages and problems:

1. The guide groove is not easy to fix, and a special frame needs to be designed to achieve it.

2. This method of providing power for hydraulic cylinders will interfere during the operation of the product, and there are potential safety hazards.

Effect of use

Since the cleaner is mounted on the unloading drum, the cleared coal is directly onto the belt; The cleaner is made into a frame-type structure, so that the cleaner becomes two lanes, and the cleaning effect is obvious; The cleaner can protrude from the splint at both ends, and after it is damaged, it can be reversed to continue to be used, and then replaced after both sides are worn, reducing the time for replacing the coal skin. The use of the cross-arm lever is to reduce the height of the roadway without occupying the lap space of the two belts during installation. The cleaner can be pressed against the drum with high contact pressure and very good cleaning results.